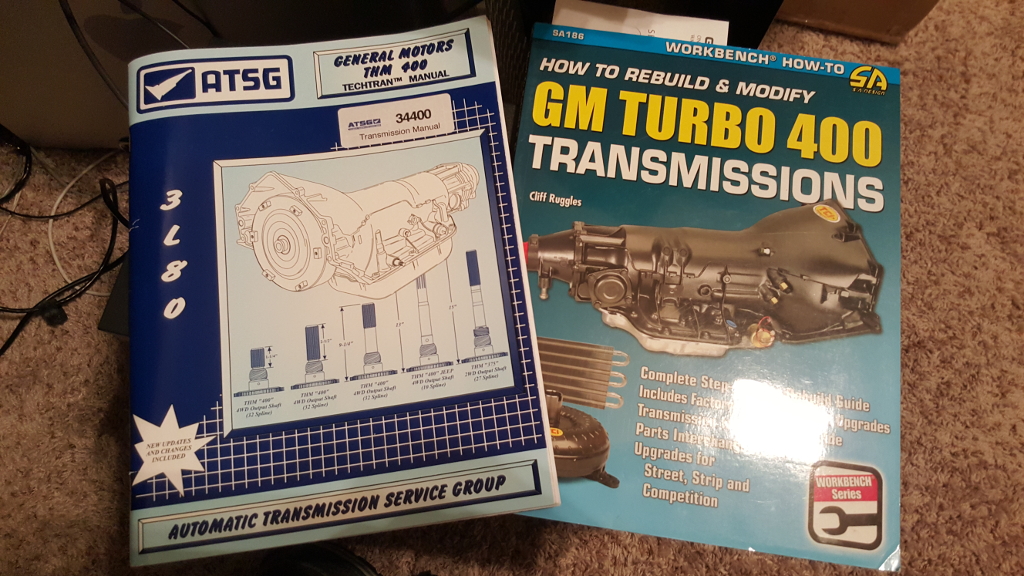

Th 400 Service Manual

General Motors introduced the TH400 transmission in 1964. It was first used in Buick and Cadillac applications, and was quickly adapted to other models. It became the workhorse of General Motors’ automatic transmissions, used in truck applications and anywhere else there was a need for a strong unit to handle high-torque engines, heavy vehicles, and towing applications. This Tech Tip is From the Full Book,.

For a comprehensive guide on this entire subject you can visit this link: SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in Forums, or with any Clubs you participate in. You can copy and paste this link to share: https://www.chevydiy.com/rebuild-gm-transmission-th400-disassembly-guide/.

Rebuilding an automatic transmission may be intimidating to some, but don’t let its complexity overwhelm you. Stay focused, complete one step at a time, and eventually you’ll have completed the task. The gear ratio for low gear is 2.48:1, 1.48:1 for second, and 1:1 in third gear. A fully assembled unit weighs nearly 135 pounds, so it’s no lightweight. Although often taunted as a bit heavy and power robbing, the TH400 makes up for it with its great strength and long-term durability in heavy-duty service.

The TH400 is also a very simple unit, and is relatively easy to overhaul. It does not require a lot of special tools, or special procedures. Most hobbyists have great success building their own units at home. The aftermarket offers plenty of heavy-duty and high-performance replacement parts for just about everything inside a TH400.

Even so, the TH400 doesn’t need a lot of help or special aftermarket parts to be a reliable and durable transmission. (I address potential weak points and recommended upgrade areas in the overhaul procedure section.). Here I recommend and outline the replacement of all of the bushings during the rebuilding process. I am also replacing all of the thrust washers. Although not mandatory for all builds, doing so produces a unit that has firmer shifting, reduced gear noise, and ultimately lasts longer once placed into service.

Remove External Components Step 1: Remove Modulator Remove the bolt for the transmission modulator retainer. Remove the modulator and the modulator valve.

A strong magnet usually pulls the valve from the case. If it doesn’t want to come out, you can use a small flattip screwdriver to help it out of the case after the valve body is removed. Step 4: Remove Oil Pan Remove the oil pan bolts, and carefully lift the oil pan up and off the transmission. It makes a good place in which to put the valve body and other associated parts removed under the pan until they can be cleaned. Remove Valve Body and Governor Filter Step 1: Remove Oil Filter Remove the special bolt that holds the oil filter in place.

TH400s used several types of filters; the one shown is the most common. Some heavy-duty truck applications use a deeper pan and extension for the filter. Very early units used a side-mounted filter. Lift the filter off the extension tube, taking care not to break or crack the plastic tube. Step 2: Remove Filter Extension and O-Ring Remove the plastic filter extension tube from the case.

Remove the O-ring from the case. It’s a common practice for builders to install two O-rings in the case, so there may be more than one; just make sure to get them out of the case at this time. Step 3: Remove Valve Body Remove the valve body bolts and remove the valve body from the case. Three of the bolts are 1/4-inch x 20 threads (shown), requiring a 7/16-inch socket. The rest of the bolts are 5/16-inch x 18 threads and require a 1/2-inch socket to remove them. They are similar to the oil pump bolts but not interchangeable, so keep them separate. Step 4: Remove Governor Filter Locate and remove the governor filter.

It should be found under the governor tube at the back of the case. It may be missing; many builders do not install one during transmission rebuilding. Remove Downshift Solenoid and Separator Plate Step 1: Remove Downshift Solenoid Bolts Remove the two 1/4-inch x 20 bolts that attach the electric downshift solenoid to the case. There were several different styles used. Some have a seal as part of the solenoid, while others require a separate seal. Step 2: Remove Downshift Solenoid Locate and remove the downshift solenoid wire from the terminal, and remove the solenoid from the transmission.

Step 3: Remove Separator Plate The separator plate and separator plate gaskets can now be removed. Remove Front Band and Low Band Apply Servos Step 1: Remove Front Band Apply Servo Lift the front band apply servo from the case. Be careful not to let the pin slide out of the piston and lose the clip that retains the spring retainer. It is best to leave this assembly intact so none of the parts get lost or rearranged during cleaning.

Th400 Service Manual Pdf

Step 2: Remove Check Balls Remove the six check balls from the case, noting their locations. Step 3: Remove Low Band Servo Cover Remove the six bolts that attach the low band servo cover to the case. Lift off the servo cover, then remove the apply piston. Note that inside the apply piston is the 1-2 accumulator and spring; remove them as well.

Step 4: Remove Parking Pawl Guide Remove the parking-pawl-guide retaining bolts and lift the guide out of the case. Remove Oil Pump, Manual Shaft and Speedometer Gear Housing Step 1: Remove Oil Pump, Manual Shaft and Speedometer Gear Housing Using a 12-point 3/8-inch socket, remove the center support retaining bolt.

This is a special hollow bolt; oil must flow through it to the intermediate clutch. Put it in a safe place until reassembly of the unit. Prior to removing the oil pump, it is a good idea to take an input shaft endplay reading. The factory used specific shims and selective thrust washers under the pump to set endplay. If you purchase a thrust washer kit, it usually comes with selective shims and thrust washers to set endplay during the rebuild.

Endplay should be no more than.030 inch, and no less than.015 inch. Step 2: Remove Oil Pump Remove the oil-pump-to-case bolts; there may be either 6 or 10 bolts, depending on the year of the transmission. Two of the pump bolt holes are threaded for 3/8-inch x 16 threads. Using a slide hammer, remove the oil pump from the case. Step 3: Loosen Nut Loosen the nut on the end of the manual shaft. Step 4: Remove Manual Shaft Remove the retaining pin for the manual shaft, and slide the manual shaft out of the case. You can now remove the transmission linkage and parking pawl shift rod from the case.

Step 5: Remove Speedometer Gear Housing Remove the speedometer gear-housing retaining bolt and retainer. Pry the speedometer gear housing from the case. Note that I have installed the end of an old speedometer cable to pry on it to avoid damaging the threads. Remove Forward Drum Clutch, Direct Drum and Band Step 1: Remove Forward Drum Clutch Get a firm hold on the input shaft and pull the forward clutch drum from the case. Step 2: Remove Direct Drum Remove the direct drum from the case.

It can be difficult to get a good grip on it; the outer snap ring and clutch and steel plates can be removed if needed (left). You can use two hooked screwdrivers to remove it (right).

Step 3: Inspect Band The band can now be removed from the case. Check the condition of the band lining and the surface on the drum where it applies. Remove Clutch Pack, Output Shaft and Low Band Step 1: Remove Clutch Pack With a large screwdriver, remove the intermediate clutch retaining ring, backing plate, and clutch pack. Step 2: Remove Retaining Ring Remove the center support retaining ring, center support, and backing spacer ring (not used on all models). Step 3: Remove Outer Shaft Remove the outer shaft that splines into the sun gear. Step 4: Remove Output Shaft Get a firm grip on the inner shaft, and lift the entire lower assembly/output shaft out of the case.

Step 5: Remove Thrust Washer Remove the thrust washer backing spacer (left) and low band (right) from the case Final Disassembly Step 1: Remove Solenoid Connector Pull the downshift solenoid electric connector from the case. Use care not to damage the unit. Use a small screwdriver, if needed, to depress the retainers. Step 2: Remove Manual Shaft Remove manual shaft from the case Step 3: Remove Manual Shaft Seal (Important!) Use a large flat-tip screwdriver to pry the manual shaft seal from the case. Use care not to damage the bore around the seal. Step 4: Remove Parking Pawl Remove the parking pawl spring. Step 5: Strip and Clean Case The case is now stripped down for cleaning.

A power washer removes heavy deposits from the case. Soaking it with engine cleaner or a heavy-duty degreaser helps the process.

The case can also be taken to a machine shop for professional cleaning. It must be clean and free of all dirt and debris prior to assembly. Written by Cliff Ruggles and Posted with Permission of CarTechBooks.

Honda Rancher 400 Service Manual

TCI Transmission Technical Manuals contain all the information a do-it-yourselfer needs to tear into a late model Chrysler, Ford, or GM transmission. Each reference guide is packed with diagrams and detailed instructions to assist you in your transmission project. Features:. Available for Chrysler, Ford, or GM Transmissions. Includes Torque Specs, Troubleshooting Charts and Repair Procedures Note: Manuals do not contain information specific to performance modifications such as TCI performs on its transmissions.